What are counterweights?

A counterweight, also known as a ballast, is a weight that is used to counterbalance an opposing force or mass of a mechanical system that usually moves in a linear or rotary motion. In linear-motion systems, such as conveyors, using counterweights that move at the same speed but in the opposite direction of the trays reduces inertial loads and vibrations. Counterweights are also used in rotating systems such as automobile tires to reduce vibrations. A heavy spot is determined by measuring the vibration without any weights. Then a counterweight is placed opposite the heavy spot to balance the load and reduce or eliminate the vibration. Other applications for counterweights include:

- lift trucks,

- draw bridges,

- crank shafts,

- elevators,

- cranes,

- grinding wheels,

- and any machine that lifts a lot of weight.

When was the counterweight first introduced?

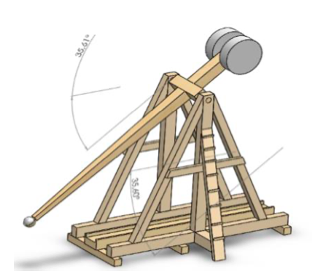

The counterweight was first introduced as part of the trebuchet [treb-yoo-shet, treb-yoo-shet]. A trebuchet is a type of catapult that uses a long arm to throw projectiles. The trebuchet first appeared in China between the 5th and 3rdcenturies BC, but it was known as the traction trebuchet, or mangonel. The mangonel consists of an arm with a bowl-shaped bucket attached to the end. A payload is placed in the bucket and the arm rotates at a high speed when released toward the target. This type of catapult was best suited for launching projectiles at lower angles, which was useful for destroying walls.

The onager predates the mangonel and is often confused with the traction trebuchet. It was first mentioned in 353 CE by Ammianus Marcellinus, who described it as a scorpion. This weapon consisted of large frame placed on the ground to where the front-end a vertical frame of solid timber was rigidly fixed. A projectile was placed in a cup, bucket, or sling which was attached to the frame that was fastened by a vertical spoke that passed through a rope bundle. To fire the projectile the spoke is forced down against the tension of twisted ropes, and then suddenly released.

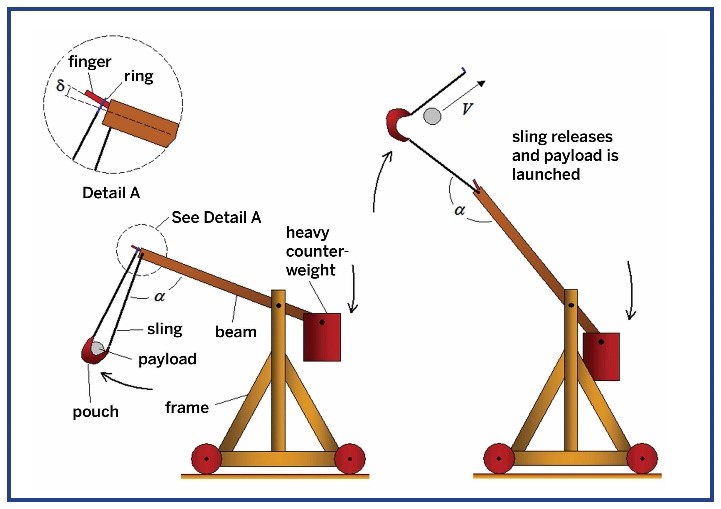

In the middle of the 12th century the counterweight trebuchet replaced its predecessor, the traction trebuchet, and remained in use through the 15th century. It’s believed that both European and Muslim locations used counterweight trebuchets before 1187, but it became a common item in siege warfare by the 1230s. The counterweight trebuchet represented the first significant mechanical utilization of gravitational energy. It influenced the development of many practical devices in the field of technology such as the pendulum clock. The use of the counterweight in the trebuchet lead to its use in many different applications.

Types of Counterweight Trebuchets:

The Fixed-Weight Counterweight

The design of the trebuchet was improved by medieval engineers by adding the counterweight. In fact, Edward I of England sent orders out to strip the church roots in the entire surrounding area of lead during the siege against the Scots castle of Stirling. It was believed that the gathered sheets of lead were melted down and then attached to the counterweight of the trebuchet. In a fixed-weight trebuchet, the weight must fall in an arc, following the arc at the end of the lever arm.

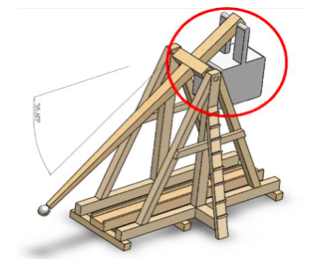

Swinging or Hinged Counterweight

In a swinging counterweight design the frame is fixed to the ground and the counterweight consists of a “basket” of rocks and dirt hanging from one end of the throwing arm. The basket allows the weight to follow a vertical descent to the ground than if it were fixed since the basket is free to swing and will adjust its fall, to a degree.

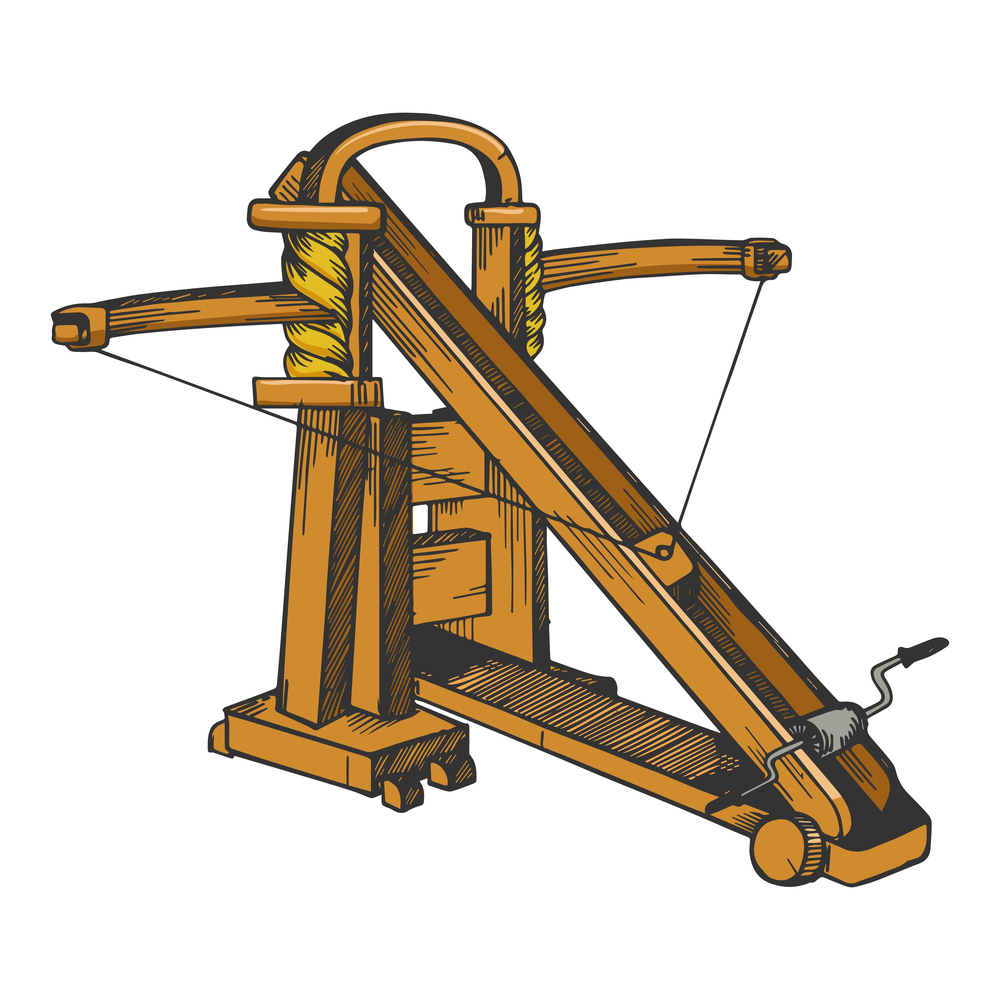

The Ballista

The ballista dates to the 12th century and is like a crossbow, but much larger. It was designed to hurl javelins or heavy balls. They were powered by torsion derived from two thick skeins of twisted cords through which were thrust two separate arms joined at their ends by the cord that propelled the missile. It was operated by pulling on the end of the lever arm, with traction being facilitated by the addition of a counterweight.

What are counterweights made of?

Counterweights are commonly made of metals – with cast iron counterweights and concreate counterweights being the most often used ones. Steel, titanium, tungsten, lead, and a few metal alloys can also be used to manufacture high-quality counterweights.

How are counterweights made?

The counterweight is manufactured by mixing concrete with a metallic material, known as casting. The concrete and metallic material are then placed into curing molds, and at least one cure accelerant is added to the mixture when the mixture is in the mold. The counterweight formed by the mold is the cured.

What industries use counterweights?

Counterweights are used for various applications in a wide variety of industries. Counterbalancing components are required for the functionality and operation of different types of vehicles, vessels, machinery, and equipment.

Aerospace, Aviation & Aeronautical

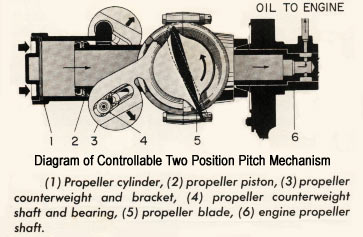

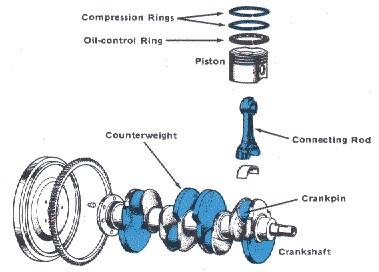

In aircraft design counterweights serve three functions: balancing control surfaces, controlling propeller pitch, and balancing crankshafts in piston engines. Counterweights are used to balance control surfaces about the axis of the hinge to avoid potentially dangerous control flutter. In piston engines the counterweights are used for both static and dynamic balancing.

Agriculture

The agriculture industry primarily engages in growing crops and raising livestock. Modern farmers use equipment such as tractors, ATVs, and plows that all require counterweights to function.

Automotive

In the automotive industry, counterweights are used on the crankshaft and are often found on the flywheel and driveshaft. They help offset vibration on the tires.

Construction

In the construction industry counterweights are used in wide variety of applications such as cranes, lifts, scaffolds, and bridges. The counterweights make systems more efficient at load bearing.

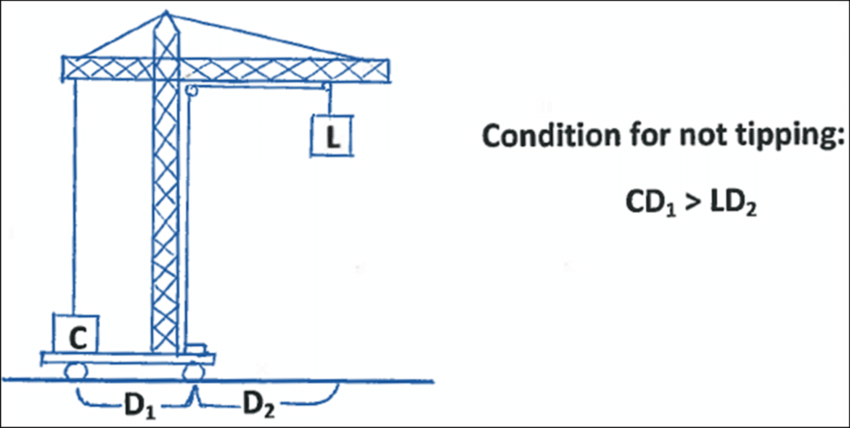

A counterweight in a crane prevents the crane from tipping over. They provide additional support when lifting or lowering loads. The counterweight is attached to the articulated arm or jib to offset the weight that the crane will be raising.

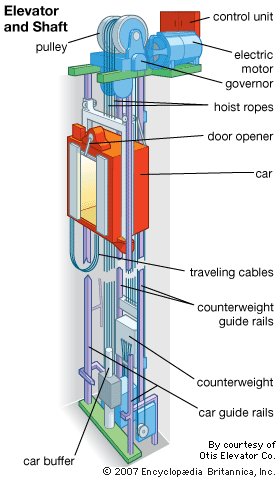

An elevator, which are also referred to as lifts, carry passengers or freight and moves in a vertical shaft between the levels of a multistory building. They are propelled by electric motors, with the aid of a counterweight, through a system of cables and pulleys.

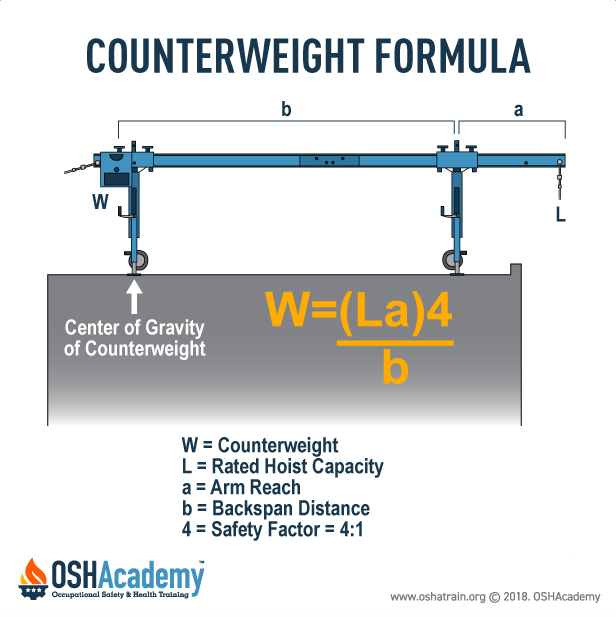

According to the OSHA, suspended scaffolds need to be counterbalanced with counterweights that is capable of resisting 4 times the tipping moment imposed by the scaffold operating at the rated load of hoist, or 1.5 (minimum) times the tipping moment imposed by the scaffold operating at the stall load of hoist, whichever is greater.

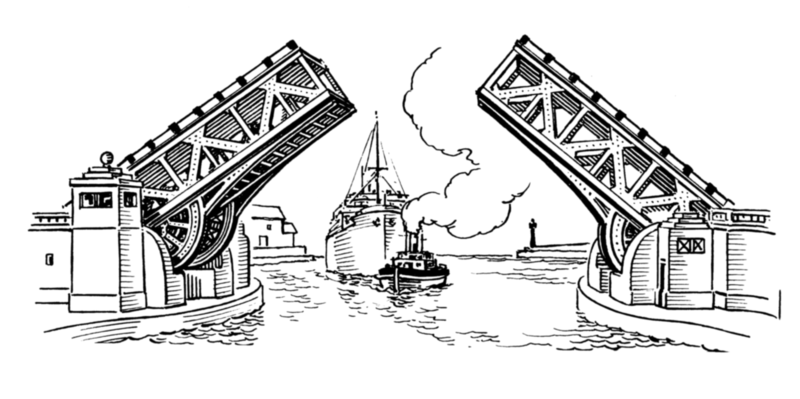

A bascule bridge (also referred to as drawbridge or lifting bridge) is a moveable bridge that is fitted with a counterweight to offset the weight of the road section. The counterweight continuously balances a span, throughout its upward swing to provide clearance for boat traffic.

Energy

The energy industry is the totality of all the industries involved in the production and sale of energy, including fuel extraction, manufacturing, refining and distribution. In this industry to produce and generate energy, equipment or machinery that require counterweights are used such as cranes, drills, scaffolds, turbines, and engines.

Oil, Gas & Mining

In the mining industry counterweights are used for elevators or lifts that move men and equipment through the various mine levels that stretch hundreds, and often thousands of feet deep. The elevators require counterweights that can carry heavy equipment, which are guided by highly tensioned steel cables that reach the depths of the mine. A counterweight is usually made of dozens of custom lead castings to anchor these cables that will provide the necessary guidance for the elevator. Since mine shafts are harsh environments using the non-ferrous metal, lead, provides longevity and reduces maintenance of the counterweight used on the elevator. It also creates a much safer environment.

Tungsten counterweights are used in the oil, gas, and mining industry as well, because the operations of these industries are generally characterized by high temperatures, and tungsten is not affected by high temperatures.

Marine (Sea)

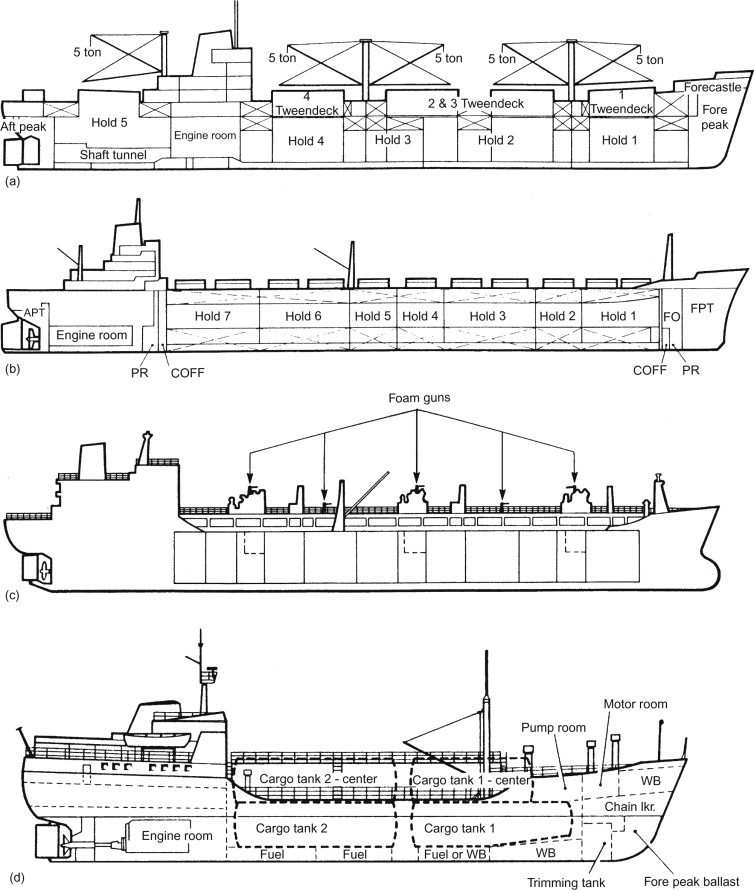

In the marine industry counterweights are used on ships, sails, submarines, and diving equipment. Counterweights are a vital part to the functionality of maritime vessels and equipment.

Since lead has a high density and is resistant to corrosion this cost-efficient metal is used as a counterweight or ballast in ships and sailing vessels.

The ballast is used to counter buoyancy on the ship to provide stability. When a ship is floating on calm water it is acted upon by two forces, weight, and buoyancy. The weight is the downward force on the ship, while the buoyancy is the upward force of the hydrostatic pressures on the hull of the ship. When the ship’s center of buoyancy equals the weight force the ship will float.

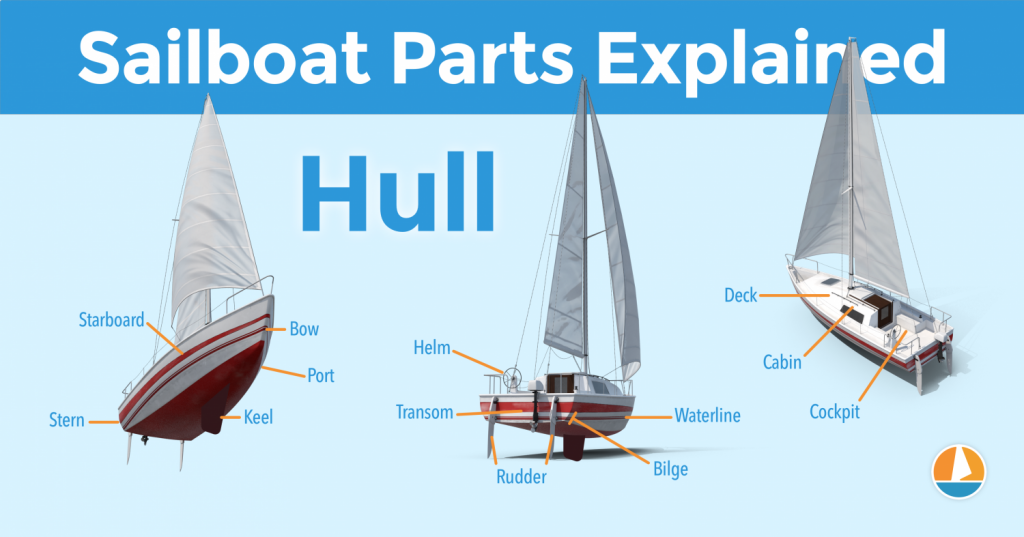

On a sailing vessel the ballast – typically made of lead, iron, or cement – is either placed on the keel or hull and acts as a counterweight to the wind’s force on the sails’ force.

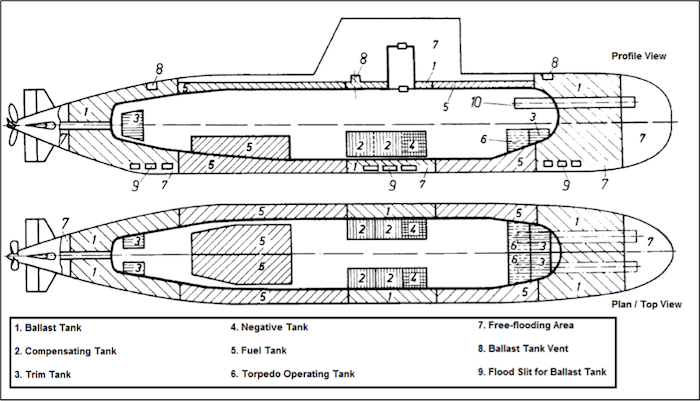

On a submarine buoyancy can be controlled by ballast tanks and trim tanks (made of concrete, steel, or lead), that can be alternately filled with water or air allowing it to sink or rise.

When diving into the sea scuba divers must wear weights to counteract the buoyancy of the other scuba equipment. The most common weight system is wearing a scuba weight belt and putting on lead weights.

Lead Counterweights Designed by Medi-Ray

Lead counterweights are a necessary product that can be casted and molded into the correct shape to be used for a wide variety of applications including ships, vehicles, planes, elevators, and any machine that lifts heavy weight. At Medi-Ray we have designed and created lead counterweights in the maritime and aeronautical industries and have been manufacturing lead products for over 50 years. Our multi-disciplined approach could provide the solution to the operational problems and high costs inherent in the many fields which draw upon metals and alloys technology. Contact us and get in touch with one of our representatives by phone or email if you’re interested in custom designed lead counterweights.

Phone: (877) 898-3003

Email: sales@mediray.com