Medi-RayTM produces a full line of Custom Manufactured Lead Products filling the wide spectrum of the Precision Lead needs of science and industry.

Medi-RayTM has been the largest supplier of radio-pharmaceutical shipping containers since 1974.

In over thirty (30) years of product development, Medi-RayTM has revolutionized the design and production of every type of shielded medical containers.

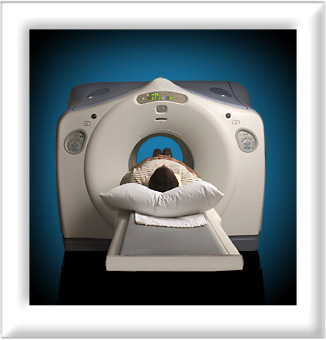

Whether you are shielding radioactive materials, X-Ray, CT, MRI or PET scanning equipment or the rooms that house them, Medi-RayTM has the shielding components you need: sheet lead and foils, adhesive backed and coated lead materials, custom components and lead stampings.

Medi-RayTM has been the largest supplier of radio-pharmaceutical shipping containers since 1974.

Medi-RayTM founders were the driving force in the development and refinement of shielded laboratory equipment and accessories for nuclear medicine. Our line of products includes numerous vial shields, syringe shields, and specialty items. Design staff

personnel can develop an entire series of accessories to complement a radio-pharmaceutical product line.

Medi-RayTM‘s experience in medical instrumentation assists customers in simplifying designs and thereby reduces production costs.

Our proprietary casting technology enables Medi-RayTM personnel to cast your intricate designs and eliminates potentially costly secondary operations.

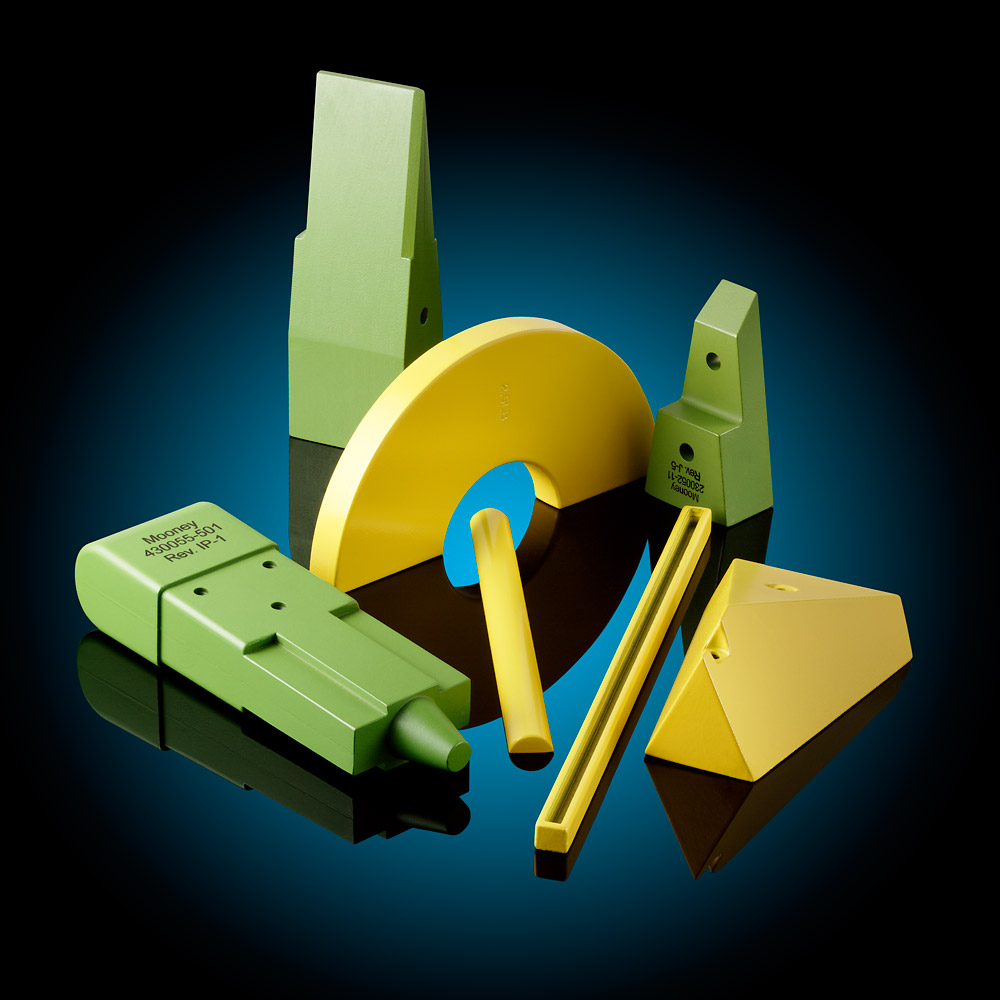

Custom counterweights have been developed for automotive, marine, environmental equipment, construction equipment, scientific laboratory applications and recreational use. Quality control procedures guarantee consistent unit weight. Specialty lead alloys can be provided to guarantee durability and functionality.

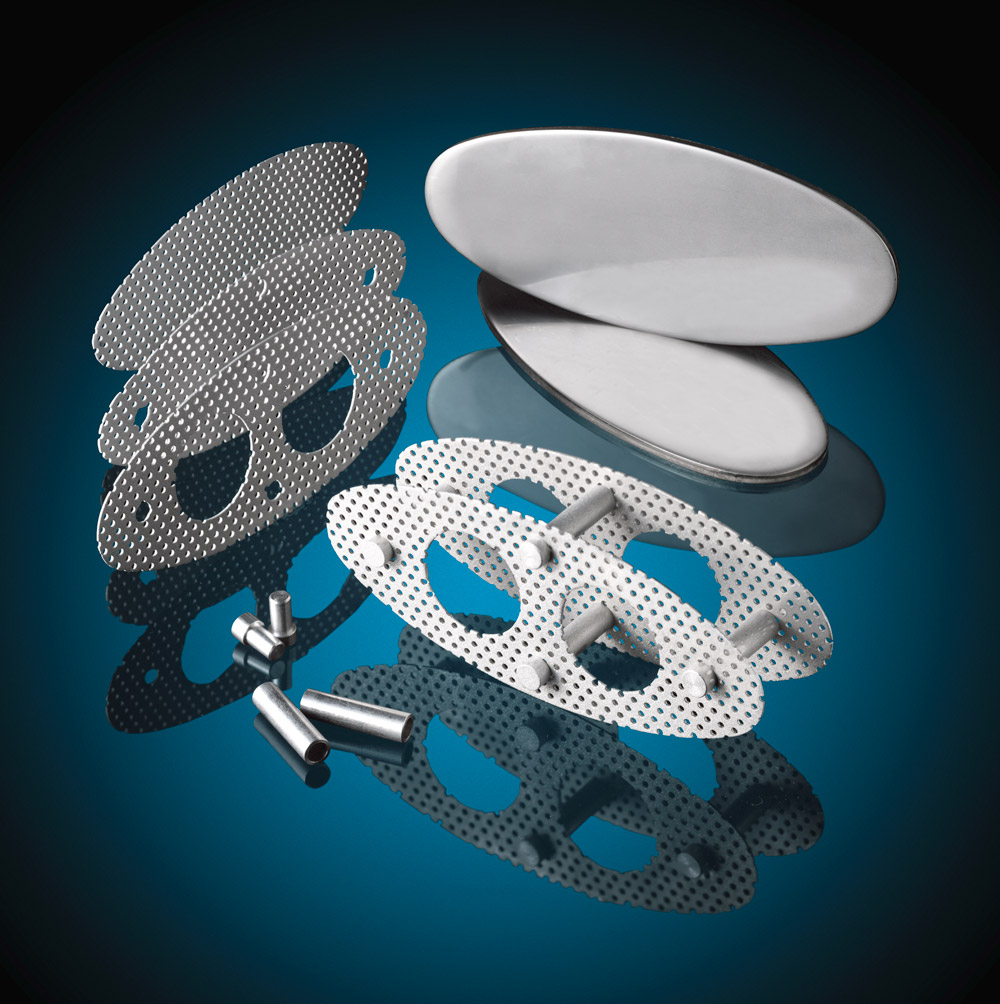

Medi-RayTM has produced numerous precision lead syringe shield designs incorporating plastic security interior and exterior components. Syringe shields undergo intensive quality control procedures including unit weight, destructive testing, proprietary porosity examination and functionality reviews.

Brass, stainless steel, and aluminum components can be supplied with a customer’s lead requirements. Precision screw machine products, inserts, sleeves, threads, nuts, bolts and clips can be insert casted, thereby guaranteeing form and fit of all parts. Medi-RayTM’s emphasis is to produce complete product assembly’s to reduce customer cost and guarantee quality.

The medical market’s need for safe, accurate and quality shielding of radioactive sources has constantly brought Medi-RayTM to the forefront of source containment.

Intricate designs have been cast as one (1) piece units, significantly increasing ease of customer

assembly and facilitation of insertion into medical equipment and testing apparatus.

Medi-RayTM supplies all standard lead brick sizes as well as interlocking configurations. Custom designs and sizes are supplied in the shortest turn-around time in our industry. Medi-RayTM’s Dura-block bricks are uniform in size and are the finest bricks available.

Medi-RayTM supplies all standard lead brick sizes as well as interlocking configurations. Custom designs and sizes are supplied in the shortest turn-around time in our industry. Medi-RayTM’s Dura-block bricks are uniform in size and are the finest bricks available.

Utilizing lead castings, sheet lead and lead foil, Medi-RayTM has developed clinic, laboratory and medical office products for all X-Ray applications.

Utilizing lead castings, sheet lead and lead foil, Medi-RayTM has developed clinic, laboratory and medical office products for all X-Ray applications.

Redesign of current medical products can provide more user-friendly products with no increase in costs.

Medi-RayTM’s proprietary fabrication machinery will enable customers to attain the greatest utilization of any sheet lead product. Medical equipment, laboratory research and dental facilities are all areas of Medi-RayTM’s expertise.

Medi-RayTM can fabricate stainless steel lined lead storage containers to custom shapes and sizes. Custom designed handles and hinges enable Medi-RayTM to provide and promote safety and durability.

Seals can be fabricated for proper fit. Epoxy and enamel coatings are available for solid lead configurations. Steel exteriors can be passivated. Stainless skids with custom casters can be provided to enhance mobility.

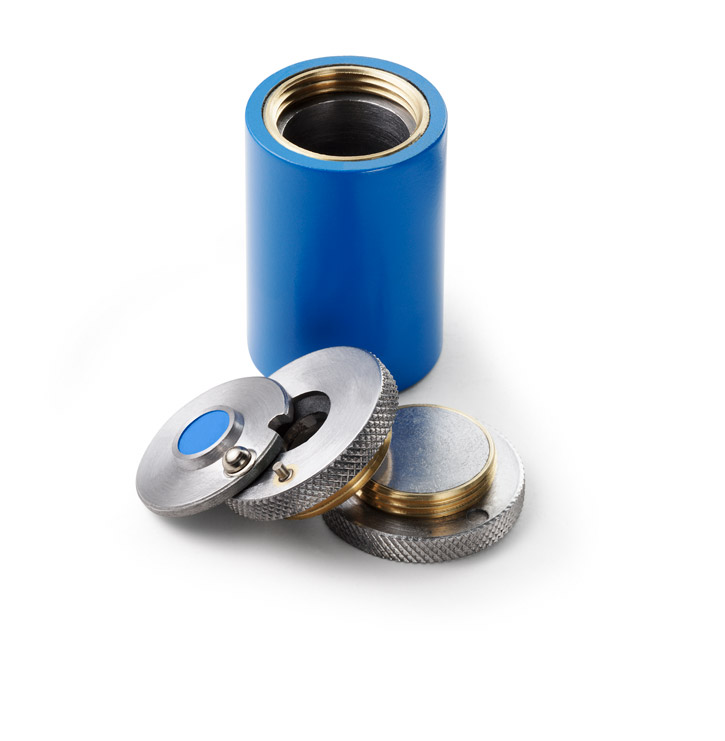

Medi-RayTM has developed a full line of ergonomically engineered vial shields that provide your clinicians with the maximum protection from exposure. Our decades of experience have allowed us to perfect the design of several types of vial shields, each engineered to meet your specific needs.

With a wide variety of closure mechanisms, color coding, lead glass viewing windows, knurled brass threaded covers, and our non-slip painted finishes we have all the product features you are looking for.

With a wide variety of closure mechanisms, color coding, lead glass viewing windows, knurled brass threaded covers, and our non-slip painted finishes we have all the product features you are looking for.

All of our vial shields are available with plastic inserts to accommodate smaller-sized vials.